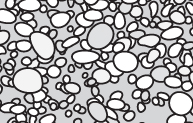

Concrete's naturally porous composition benefits greatly from the application of densifiers — chemical solutions designed to improve concrete's surface hardness, density and shine. When you apply a liquid densifier to concrete during coloring or polishing, the solution reacts with the free lime or calcium hydroxide present in the concrete to solidify it, making the concrete surface much less permeable and more resistant to stains. The most common uses: on hard troweled industrial floors, polished concrete and decorative stained concrete.

Kinds of densifiers

There are many kinds of densifiers, classified into two "generations." Magnesium, potassium and sodium silicate are first-generation products and react with the calcium hydroxide in the concrete. The reaction starts immediately but continues slowly, due to the natural closeness of the pH of concrete. This application process is more caustic and labor-intensive.

Second-generation densifiers are lithium silicate-based densifiers with nano-sized technology and waterborne colloidal silica from nano-sized amorphous particles mechanically suspended in water.

Second-generation densifiers are lithium silicate-based densifiers with nano-sized technology and waterborne colloidal silica from nano-sized amorphous particles mechanically suspended in water.

The lower pH of this colloid makes the reaction much faster and increases more reaction points with the free lime in the concrete. Plus, the suspension of the silicate particles allows the solution to penetrate much deeper before this reaction takes place.

H&C® Clear Liquid Hardener & Densifier

H&C Clear Liquid Hardener & Densifier is an amorphous colloidal silica solution designed to both harden and densify concrete. This proprietary formulation penetrates and reacts with concrete faster than conventional systems and produces a harder, more uniform surface. What exactly makes this densifier unique? It allows the solution to penetrate deeper — 3/16 to 1/4 of an inch — into the concrete before solidifying, creating better protection for the concrete. Its work time of 20 minutes saves product and costly labor time.

H&C Clear Liquid Hardener & Densifier can be used on both interior and exterior concrete. When using on exterior concrete, be sure that the concrete has not been previously sealed with a curing compound. Curing agents, clear sealers and any previous surface coating should be chemically or mechanically removed.

Polishing and application

On plain hard-troweled concrete (industrial floors). In all cases, the concrete needs to be clean; reasonably dry; and free from grease, oils and any other contaminants. It's recommended that the floor be profiled with a 100- and then 200-grit floor grinder. This opens the surface and allows the best penetration of the solution. Liberally apply the solution across 400 to 500 square feet of surface and agitate for about 15 to 20 minutes. Do not allow drying while penetration is taking place. After penetration, remove excess solution with water and a floor scrubber.

- For polished concrete. Follow the same steps as above, but continue to grind and polish. After polishing, use H&C® Lithium Protective Finish to increase surface hardness and gloss.

- When opting for color dye or stain. Preparation is the same as hard-troweled concrete: Add color dye or stain halfway through the grinding process. For instance, polish with 30, 50, 100, 200 and 400 grit, then add color and densifier. Continue polishing using resin bond diamonds 800, 1,500 and 3,000 grit. After polishing, use H&C Lithium Protective Finish to increase surface hardness and gloss. The protective finish should be burnished with a high-speed buffer to achieve maximum hardness and sheen.

Dependable business builder

Densifying and polishing floors is a smooth process using H&C Clear Liquid Hardener & Densifier, with its deep, quick penetration and ease of application. Success is virtually guaranteed every time. Beautifully executed projects will lead to more satisfied customers, opportunities and profits.